In November 2008 we became the proud owners of Sabre Six convertible, 700 RUR. This is one of only two such convertibles ever made by Reliant.

Initially a few jobs were undertaken including the installation of newly refurbished carburettors, nice new mat black silicon radiator hoses and new radiator fan and thermostatic switch and in February 2009, and to our delight (and a little surprise), the car passed its MOT.

It soon became apparent to us that the semi-leading (flailing) arm front suspension was unsuited to this car. The arrangement was based on the original Ballamy inspired chassis that Reliant developed for the Sabre Four. The extra weight of the six cylinder engine resulted in extremely heavy and lifeless steering with no self centring, a poor turning circle and severe kickback. Reliant soon realise this and after only 18 cars converted the front suspension to twin wishbone type with rack and pinion steering.

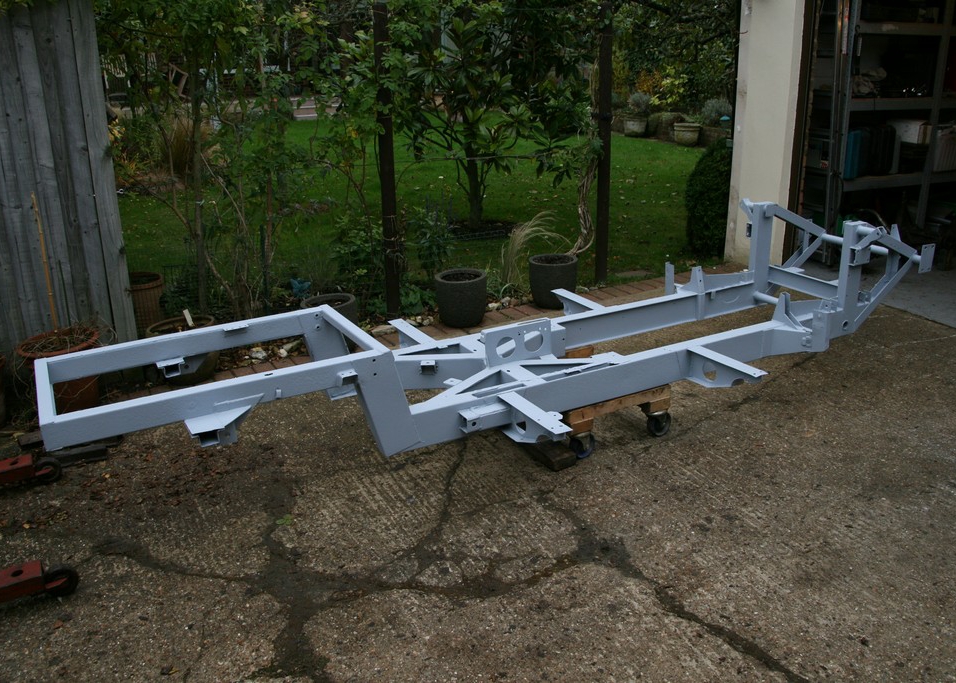

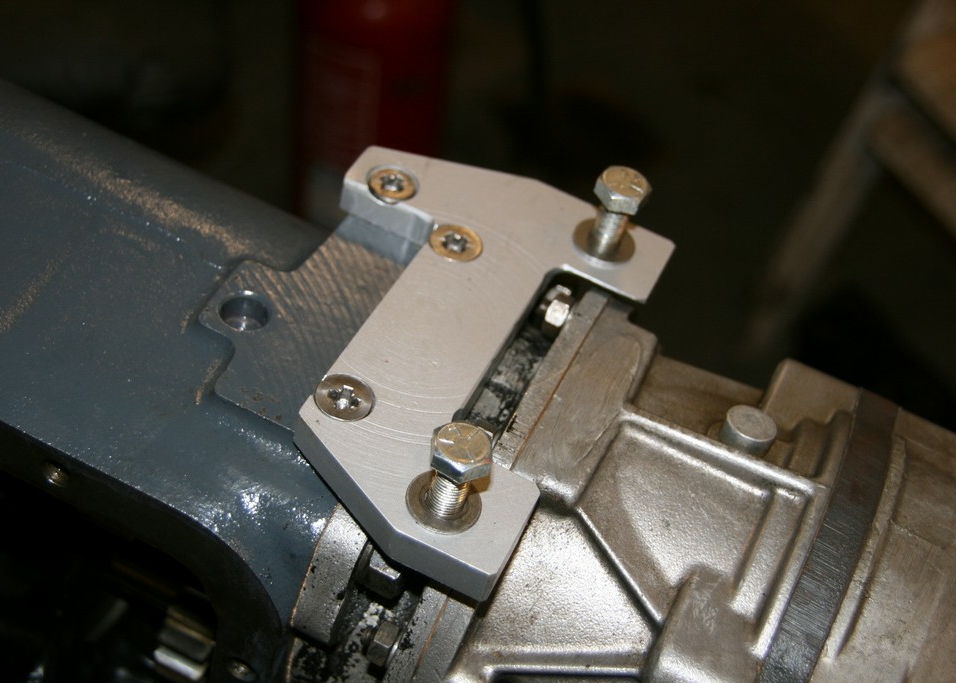

Purists might like to skip this paragraph. We decided to replace the original flailing arm system with a wishbone system identical to that of the later Sabre Sixes. The work was carried out by Iain Daniels Classic Car Engineering. At the same time the steering was replaced with a later type rack and pinion system. This was obviously a big job but actually not too difficult (Danny's words). When Reliant made the change they designed it in a way such that a minimum of changes were necessary to the chassis. Danny fabricated a new chassis front section from the suspension upright forward and replaced the existing front section from a convenient weld. I had accumulated various bits of wishbone suspension components over the years (as you do) and these have been refurbished as necessary and used for the new set up. Danny had undertaken this modification on his own race car so was well up for the challenge. To appease, as best as we can, the purists who might think that car should have remained original, we have retained all the original parts so it would be possible to revert the car back to its original specification. We are delighted to report that the steering has been completely transformed for the better. In particular the weight of the steering is drastically reduced as is the turning circle which I hadn't particularly thought about. As part of the work the front brake callipers have been replaced with SE5/early 6 three pot callipers and the brake master cylinder has been replaced with a larger 7/8in unit.

Whilst he had the car Danny also reconditioned the engine which had been consuming vast quantities of oil. This turned out to be a bit of a challenge because components such as bearings, pistons and piston rings are becoming ever harder to find. The bore was found to be standard size. However it was also found to have liners fitted. Apparently this was often done by the factory on new engines. So for the refurbishment new liners with standard bores were fitted allowing use of the original standard pistons.

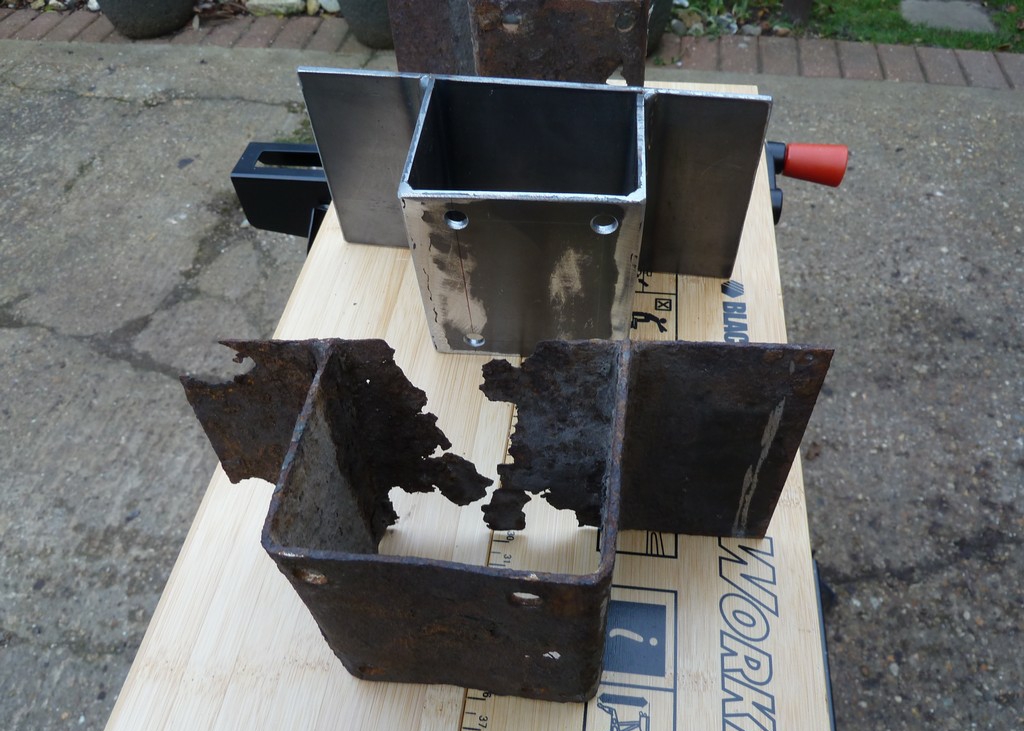

The bottom two photos show the front suspension before and after the change.

We continue to enjoy the benefits of RUR's new suspension and engine. We have completed several thousand miles in the car since the work was completed including a 1700 mile trip to the south of France in September 2011. As Jaki says "At last I can actually drive RUR and enjoy it!! Tony was keen for me to try the car out and prove that we had done the right thing in changing the front suspension and I believe we have. It is now a joy to drive."